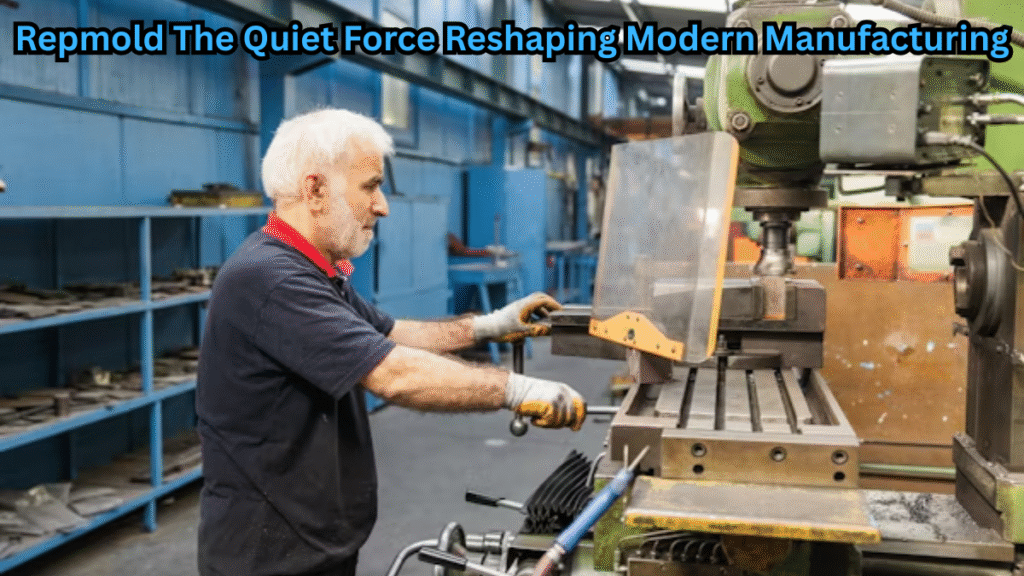

When someone asks, “What is repmold?” the clearest answer is this: repmold refers to a specialized molding process that combines repeatable precision with advanced material science, giving industries—from automotive to healthcare—a way to make stronger, lighter, and more efficient parts. In fewer than a hundred words, that’s the heart of the matter: repmold is not just a technique but a philosophy of how we replicate form with minimal waste and maximal consistency. For manufacturers, the question isn’t whether repmold matters. It’s how quickly they can adopt it before being left behind.

Understanding Repmold at Its Core

The term repmold is a fusion of two ideas: repetition and molding. It represents a family of techniques that prioritize reproducibility in shaping raw materials into precise components. Unlike older molding processes that often suffered from inconsistencies across large production runs, repmold ensures that the first unit and the one-millionth share the same tolerances.

At its core, repmold’s draws on three pillars:

- Precision engineering to control dimensions within microns.

- Material flexibility allowing metals, polymers, and composites to be used interchangeably.

- Process efficiency that reduces energy consumption and waste.

Think of repmold’s as the quiet scaffolding of everyday objects—from the clip in a pen to the shell of a medical device. It is invisible, but everywhere.

The Evolution of Molding Technologies

Molding dates back thousands of years, when artisans used clay and simple forms to reproduce vessels. The industrial revolution brought casting, injection molding, and die-casting into mainstream use. Yet these methods were often plagued by error margins.

Repmold’s emerged from the late 20th century drive toward “zero-defect manufacturing.” Engineers realized that as devices became smaller—semiconductors, micro-sensors, even medical implants—the acceptable tolerance for mistakes shrank dramatically. Traditional molds could not keep up.

The innovation of repmold’s was not in inventing new materials, but in reimagining how molds themselves were designed, monitored, and repeated. Advanced CAD software, CNC machining, and sensor-driven feedback loops made the dream of perfect reproducibility tangible.

Why Repmold’s Matters Today

The modern economy thrives on scale. An automaker cannot afford for 5% of its dashboards to be faulty, nor can a healthcare supplier risk irregularities in syringes. Repmold’s addresses these challenges directly.

Industries where repmold’s is indispensable:

- Automotive – dashboards, engine components, and lightweight panels.

- Consumer electronics – smartphone shells, connector housings, micro-frames.

- Healthcare – surgical tools, drug delivery systems, prosthetics.

- Aerospace – turbine blades, cabin interior fittings, lightweight structural components.

Each of these sectors benefits from the consistency that repmold offers. But more importantly, repmold enables innovation—manufacturers can experiment with new designs knowing that once perfected, they can be reproduced flawlessly.

The Science Behind Repmold

To appreciate repmold’s, one must understand the science at play. It is not a single process but an ecosystem where multiple technologies converge.

Key Elements of Repmold

- Tooling

High-grade steel or ceramic molds are produced with microscopic precision. They often incorporate cooling channels and thermal regulation systems. - Sensors

Modern repmold’s setups use embedded sensors that track temperature, pressure, and fill rates in real-time. - Feedback Loops

Artificial intelligence systems adjust parameters automatically, ensuring uniformity. - Material Science

Polymers with enhanced flow properties, metals with controlled grain structures, and composites with optimized fiber orientations are specifically developed for repmold.

A simplified table helps illustrate the differences:

| Feature | Traditional Molding | Repmold Approach |

|---|---|---|

| Tolerances | 50–100 microns | 5–10 microns |

| Waste Output | High | Minimal |

| Energy Efficiency | Moderate | Optimized with smart sensors |

| Scalability | Limited after 100,000 runs | Virtually unlimited |

Human Voices from the Industry

Quotes from engineers and managers shed light on why repmold has become a cornerstone technology:

- “Repmold’s gave us the confidence to launch products with complex geometries. Without it, our error rates would have sunk us.” — Senior Automotive Engineer

- “In healthcare, reproducibility isn’t just about efficiency—it’s about safety. Repmold’s ensures a syringe is always a syringe.” — Medical Device Specialist

- “The beauty of repmold is that it democratizes perfection. You don’t need to be a massive corporation to achieve consistency anymore.” — Mid-sized Manufacturer CEO

- “When you walk through a repmold facility, you see fewer people, more sensors, and a constant rhythm of precision.” — Industrial Analyst

Sustainability and Repmold

The environmental conversation around manufacturing is unavoidable, and repmold has a unique position in it. Because repmold minimizes waste, energy use, and scrap, it contributes significantly to sustainability goals.

- Reduced Waste: Each mold run produces nearly identical results, lowering defective output.

- Recyclable Materials: Repmold’s often works with recyclable thermoplastics and alloys.

- Energy Savings: Smart cooling systems reduce electricity demand.

- Lifecycle Longevity: Durable molds last longer, reducing the need for frequent replacements.

This is crucial at a time when industries are under pressure to meet carbon targets while keeping costs manageable.

Challenges and Limitations

Despite its strengths, repmold’s is not without challenges.

- High Initial Investment – Advanced tooling and sensor-driven molds require substantial upfront capital.

- Skilled Workforce – Technicians must be trained not only in mechanical engineering but also in data analytics.

- Maintenance Costs – While molds last longer, when they fail, repairs are costly.

- Material Compatibility – Not all materials can be easily adapted to repmold.

For small manufacturers, these hurdles can delay adoption. Yet, as with most industrial innovations, costs typically decrease over time.

Future Directions of Repmold

Looking forward, repmold’s is evolving alongside broader manufacturing trends:

- Integration with 3D Printing: Hybrid systems that use additive manufacturing for mold prototyping followed by repmold’s for scaling.

- AI-Driven Predictive Maintenance: Systems that detect potential mold failures before they occur.

- Nano-Repmolding: Techniques applied at the nanoscale for microchips and medical implants.

- Decentralized Production: Small, modular repmold facilities near consumption centers to reduce logistics emissions.

The next decade is poised to see repmold expand beyond its traditional domains into fields like renewable energy, robotics, and even personalized consumer goods.

Case Study: Repmold in the Automotive Sector

Consider an electric vehicle (EV) manufacturer. The company needed lightweight panels that could be produced at scale without compromising strength. Traditional stamping methods led to inconsistencies, raising safety concerns.

By adopting repmold’s , the manufacturer achieved:

- 40% reduction in defective parts

- 25% decrease in material waste

- 15% improvement in production speed

- Enhanced safety compliance across regions

The result was not just cost savings, but a faster rollout of new EV models.

The Social and Cultural Dimension

It’s easy to view repmold as a purely technical phenomenon, but there is also a human element. Workers once engaged in repetitive manual inspections are now retrained as digital operators. Communities that host repmold facilities see cleaner, quieter production. Consumers, although unaware, experience safer, better-designed products.

In this sense, repmold mirrors broader industrial trends: automation, sustainability, and human-machine collaboration.

The Economics of Adoption

The financial dimension of repmold adoption is layered. A detailed breakdown helps illustrate:

| Cost Factor | Traditional Approach | Repmold Approach |

|---|---|---|

| Tooling Investment | Low to moderate | High upfront |

| Operational Efficiency | Moderate | Very high |

| Waste Management | Costly | Minimal cost |

| Long-Term ROI | Uncertain | Strong and predictable |

The shift is best understood as moving from short-term affordability to long-term resilience.

Repmold and Global Supply Chains

The pandemic revealed how fragile supply chains can be. Repmold offers a degree of resilience. Because repmold processes are modular and standardized, they can be replicated across multiple regions. This decentralization reduces dependency on a single supplier.

Furthermore, companies adopting repmold often discover that they can source locally available materials, further insulating themselves from geopolitical disruptions.

A Glimpse Ahead

It is tempting to see repmold as just another incremental advance. Yet, history shows that behind every leap in industry lies a humble process that most people never hear about. Steam engines, assembly lines, and semiconductor lithography once occupied similar positions.

Repmold may well be the hidden backbone of the next industrial renaissance.

Conclusion

Repmold is more than a niche technical method. It is the crystallization of humanity’s desire for precision, efficiency, and reliability. From automotive panels to surgical implants, its reach is expanding every year. It reduces waste, enhances safety, and drives innovation.

Perhaps most importantly, repmold represents a philosophy of replication: that what works once should work a thousand times without flaw. In an era where the smallest defect can have enormous consequences, repmold provides not just a method of making things, but a way of ensuring trust in the things we make.

As industries worldwide grapple with the twin pressures of sustainability and competitiveness, repmold stands as a quiet yet profound answer.