In today’s fast-evolving technological and industrial landscape, trifak has emerged as a term attracting growing attention across multiple sectors. Whether you are a researcher, industry professional, or an informed reader seeking clarity, understanding trifak is essential. At its core, trifak represents a unique convergence of materials, methods, and innovation, with applications spanning science, technology, and environmental solutions. This article provides a thorough exploration of trifak, its practical uses, advantages, and potential to influence future developments.

Trifak is not merely a product or a simple concept; it is a framework that integrates modern technological insights with traditional approaches to improve efficiency and sustainability. By reading this guide, you will gain a deep understanding of trifak, including its origins, key features, applications, and emerging trends.

Understanding Trifak: Definition and Concept

Trifak’s can be broadly defined as a multifunctional system designed to optimize processes in various industries. Its foundation lies in integrating three core principles: efficiency, adaptability, and sustainability. While the term trifak’s may seem novel, it is increasingly being adopted in engineering, environmental sciences, and industrial automation due to its versatility.

The concept of trifak’s can be summarized in three pillars:

- Efficiency: Trifak-based systems aim to reduce resource wastage while increasing productivity.

- Adaptability: These systems can adjust to different operational conditions without compromising output quality.

- Sustainability: Trifak promotes environmentally responsible practices through minimal resource consumption and waste reduction.

By combining these principles, trifak’s serves as a blueprint for innovation, providing a strategic advantage to industries embracing it.

Historical Background of Trifak

The origins of trifak’s trace back to experimental methods in the early 21st century when researchers sought integrated approaches to enhance industrial efficiency. Initially developed in controlled laboratory environments, tr’sdemonstrated remarkable potential in materials science, automation, and environmental engineering. Over the past decade, trifak’s has transitioned from an experimental concept to a practical tool applied in real-world scenarios.

Early pioneers emphasized three foundational areas:

- Material Optimization: Reducing cost while enhancing durability and performance.

- Process Integration: Streamlining multiple operational processes into a cohesive system.

- Environmental Responsibility: Minimizing ecological impact while maintaining productivity.

These foundational principles continue to guide modern applications of trifak.

How Trifaks Works: Mechanisms and Technology

At its core, trifak leverages a combination of mechanical, digital, and chemical processes to achieve its objectives. Its mechanisms vary depending on the field of application but share common characteristics: precision, efficiency, and flexibility.

Key Components of Trifak’s Systems

| Component | Function | Benefits |

|---|---|---|

| Sensor Module | Detects operational variables and environmental conditions | Enhances real-time monitoring and adaptability |

| Control Unit | Processes data and adjusts system parameters | Ensures optimal performance with minimal errors |

| Actuator Network | Implements the adjustments in machinery or processes | Improves accuracy and reduces manual intervention |

| Material Interface | Facilitates interaction with different raw materials | Supports versatility across industries |

| Data Analytics Engine | Collects and analyzes operational data | Provides insights for continuous improvement |

This table illustrates how trifaks systems are designed to integrate multiple layers of functionality, making them highly efficient and adaptable.

Operational Flow

The typical operational workflow of a trifaks system includes:

- Data Collection: Sensors gather real-time information.

- Processing: The control unit analyzes the data.

- Decision Making: Automated algorithms determine the optimal action.

- Execution: Actuators implement changes in the process.

- Feedback Loop: Continuous monitoring ensures adjustments remain effective.

This loop ensures that trifaks systems can dynamically respond to changes, offering unmatched flexibility.

Applications of Trifaks Across Industries

Trifak’s versatility allows it to be applied in multiple sectors. Below are some of the most prominent applications:

1. Industrial Manufacturing

In manufacturing, trifask systems optimize production lines by reducing waste and enhancing efficiency. By integrating sensor-based monitoring and automated controls, factories can achieve higher output with lower energy consumption. Many automotive and electronics manufacturers are increasingly adopting trifaks systems for quality control and process optimization.

2. Environmental Management

Tri-fak offers significant potential in environmental conservation. Its ability to monitor and adjust processes in real-time helps reduce emissions, optimize water usage, and improve waste management. For example, in wastewater treatment plants, trif-ak systems enable precise chemical dosing and energy-efficient operations.

3. Agriculture

Precision farming benefits greatly from trifak’s technology. By combining soil sensors, automated irrigation, and data analytics, farmers can maximize crop yields while minimizing water and fertilizer use. Trifak’s contributes to sustainable agricultural practices and enhances resource efficiency.

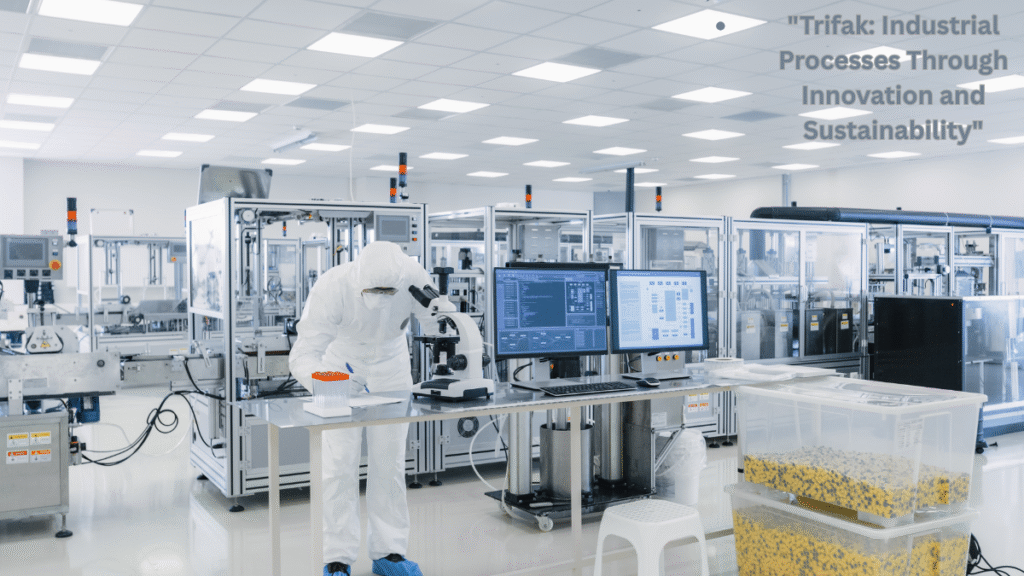

4. Healthcare and Laboratory Research

In healthcare, trifak’s systems assist in laboratory automation, drug manufacturing, and patient monitoring. They streamline repetitive processes and enhance accuracy, reducing human error. In research labs, trifak’s enables efficient testing protocols, particularly in chemical and biological experiments.

5. Energy Sector

Trifak’s systems optimize energy consumption in power plants and renewable energy installations. Through predictive monitoring and adaptive controls, they ensure efficient energy generation and storage, contributing to sustainability and cost reduction.

Benefits of Trifak

The adoption of trifak’s offers numerous advantages:

- Operational Efficiency: Reduced downtime and increased throughput.

- Cost Savings: Optimized resource usage lowers operational costs.

- Environmental Responsibility: Minimized emissions and waste contribute to sustainability.

- Adaptability: Systems can adjust to changing conditions automatically.

- Data-Driven Insights: Continuous feedback allows for informed decision-making.

Challenges and Limitations

Despite its benefits, trifak is not without challenges:

- High Initial Investment: Implementing trifak systems can be costly.

- Technical Complexity: Requires specialized knowledge for operation and maintenance.

- Integration Issues: Existing infrastructure may need upgrades.

- Data Privacy Concerns: Continuous monitoring involves sensitive information.

Addressing these challenges requires careful planning, skilled personnel, and incremental implementation.

Emerging Trends in Trifak

As industries continue to evolve, trifak is expected to adapt and expand. Some emerging trends include:

- AI Integration: Using artificial intelligence to enhance predictive capabilities.

- IoT Connectivity: Linking trifak systems with Internet of Things devices for comprehensive monitoring.

- Sustainable Innovations: Further reducing environmental impact through eco-friendly materials.

- Global Adoption: Increased deployment across emerging markets for industrial and environmental applications.

Case Studies

Case Study 1: Automotive Industry

A leading automotive manufacturer integrated trifak systems in its assembly lines. Result: 20% increase in productivity, 15% reduction in energy usage, and significant improvement in product quality.

Case Study 2: Wastewater Management

A municipal wastewater treatment plant implemented trifak-based automation. Result: 30% reduction in chemical usage, 25% energy savings, and more efficient waste processing.

Case Study 3: Precision Agriculture

A farm in California utilized trifak-enabled irrigation and soil monitoring systems. Result: Water consumption reduced by 40%, crop yield increased by 18%, and fertilizer use optimized.

Comparison with Traditional Systems

| Feature | Trifak Systems | Traditional Systems |

|---|---|---|

| Efficiency | High | Moderate |

| Adaptability | Dynamic | Limited |

| Environmental Impact | Low | High |

| Data Analytics | Advanced | Minimal |

| Cost | High initial, long-term savings | Lower upfront, higher operating costs |

How to Implement Trifak

Implementing trifak requires a structured approach:

- Assessment: Evaluate current processes and infrastructure.

- Planning: Identify areas where trifak can provide maximum impact.

- Installation: Deploy trifak components and integrate with existing systems.

- Training: Educate personnel on operating and maintaining the system.

- Monitoring: Continuously track performance and optimize operations.

Future of Trifak

The future of trifak looks promising as industries increasingly prioritize efficiency, sustainability, and automation. Research and development continue to enhance its capabilities, particularly in AI integration, renewable energy, and resource management. Experts predict widespread adoption in sectors like smart cities, autonomous manufacturing, and advanced healthcare.

Conclusion

Trifak represents a transformative approach across multiple domains. Its combination of efficiency, adaptability, and sustainability makes it a critical tool for industries striving for innovation. From manufacturing to environmental management, trifak systems are proving their value in optimizing processes, reducing costs, and minimizing ecological impact. Understanding and leveraging trifak can provide a significant competitive advantage in today’s rapidly evolving industrial and technological landscape.

Frequently Asked Questions (FAQs)

1. What is trifak?

Trifak is a multifunctional system designed to enhance efficiency, adaptability, and sustainability across various industries.

2. Which industries benefit the most from trifak?

Industries like manufacturing, agriculture, healthcare, energy, and environmental management gain significant advantages from trifak.

3. What are the main components of a trifak system?

Key components include sensors, control units, actuators, material interfaces, and data analytics engines.

4. Are trifak systems expensive to implement?

They require high initial investment but provide long-term savings through efficiency, reduced waste, and optimized operations.

5. How does trifak improve sustainability?

Trifak reduces resource consumption, minimizes waste, and optimizes energy usage, contributing to environmental conservation.