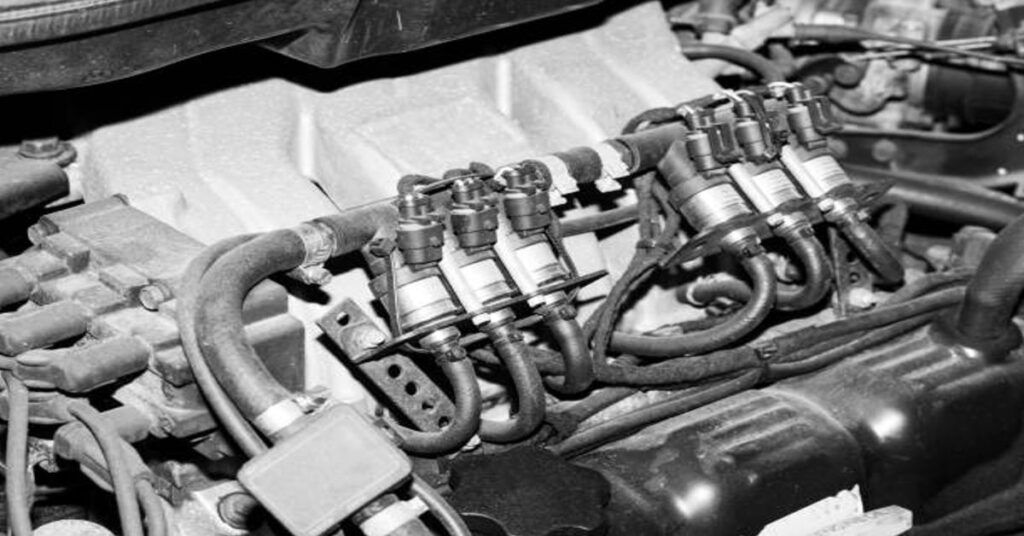

Modern automotive engines rely on precise fuel delivery systems to achieve peak performance, fuel economy, and reliability. Among the most important components of this system are fuel injectors, which deliver a controlled spray of fuel into the engine’s combustion chamber. Over time, however, these injectors can become clogged with carbon deposits, varnish, and impurities from fuel. This buildup affects spray patterns, combustion efficiency, and overall vehicle performance. One of the simplest and most cost-effective ways to maintain your engine’s health is to use a fuel injector cleaner.

This article provides an in-depth understanding of what fuel injector cleaners are, how they work, when and how to use them, and the measurable benefits they bring to both gasoline and diesel engines.

1. Understanding the Role of Fuel Injectors

Fuel injectors are electronically controlled valves designed to atomize and deliver fuel at the correct pressure and timing into the combustion chamber. The process is crucial because it ensures complete combustion, which translates to higher fuel efficiency, reduced emissions, and smoother performance.

Each injector must deliver a fine mist of fuel rather than a stream. This atomization enables better mixing of fuel with air, leading to an efficient burn. However, because modern fuels often contain additives and impurities, the injectors are susceptible to buildup. Over thousands of miles, microscopic residues can accumulate, causing:

- Poor spray patterns

- Uneven fuel distribution

- Misfires or hesitation

- Decreased fuel efficiency

- Increased emissions

To counter this gradual degradation, fuel injector cleaners are introduced into the fuel system.

2. What is a Fuel Injector Cleaner?

A fuel injector cleaner is a specially formulated chemical additive designed to dissolve and remove carbon deposits, gum, varnish, and other residues from injectors and fuel system components. It is typically added directly into the fuel tank, where it mixes with gasoline or diesel and passes through the injectors during operation.

Composition of Fuel Injector Cleaners

Although different brands may use varying formulations, most effective fuel injector cleaners contain some or all of the following active ingredients:

| Chemical Component | Function in the Cleaner |

|---|---|

| Polyetheramine (PEA) | The most effective detergent; dissolves stubborn carbon deposits and prevents reformation. |

| Polyisobutylene (PIB) | Cleans intake valves, carburetors, and injectors; helps prevent fuel oxidation. |

| Polyisobutylene Amine (PIBA) | Works as a detergent and dispersant; helps maintain injector cleanliness. |

| Carrier Solvents | Dissolve and transport the active chemicals through the fuel system. |

Among these, PEA-based cleaners are widely considered the most powerful and effective because they work even under high temperatures, penetrating and dissolving hard carbon layers.

3. How Fuel Injector Cleaners Work

When you add the cleaner to the fuel tank, it mixes with the gasoline or diesel fuel. As the engine runs, this treated fuel passes through the injectors, intake valves, combustion chamber, and exhaust system. The chemical agents in the cleaner begin breaking down deposits and residues that have formed over time.

Step-by-Step Cleaning Process:

- Introduction into the Fuel System: The cleaner blends with the fuel and travels through the fuel lines.

- Injection Phase: The treated fuel is sprayed through the injectors. The detergent components interact with the buildup inside the injector nozzle, gradually dissolving it.

- Combustion Chamber Cleaning: Once inside the chamber, residual deposits on pistons, valves, and cylinder walls are also loosened.

- Emission Reduction: The byproducts of the cleaning process are safely burned during combustion and expelled through the exhaust.

This process helps restore normal spray patterns and improves the overall efficiency of the combustion process.

4. Signs That Indicate You Need a Fuel Injector Cleaner

Although modern engines are more resilient than older ones, contamination and deposits are inevitable over time. The following are common symptoms that indicate your injectors may be dirty or clogged:

- Rough Idling: The engine may shake or feel uneven when running at low RPMs.

- Reduced Fuel Efficiency: You may notice more frequent refueling even with the same driving habits.

- Difficulty Starting the Engine: Clogged injectors can disrupt the air-fuel ratio needed for ignition.

- Poor Acceleration: A delayed or sluggish throttle response often signals injector issues.

- Increased Emissions: Black smoke or a strong fuel smell from the exhaust can be signs of incomplete combustion.

- Knocking or Pinging Sounds: Uneven combustion caused by poor fuel atomization can create knocking noises.

If you observe two or more of these symptoms, it’s likely time to clean your injectors with a high-quality cleaner.

5. Benefits of Using Fuel Injector Cleaners

Using a good injector cleaner is not merely about preventing problems—it actively enhances the engine’s performance and longevity. Below are the key advantages:

1. Improved Fuel Economy

A clean injector ensures that fuel is sprayed in the right quantity and pattern, reducing waste and optimizing combustion. This can improve mileage by up to 5–10% depending on the engine’s condition.

2. Enhanced Engine Performance

After cleaning, you may notice smoother acceleration, improved throttle response, and quieter engine operation.

3. Reduced Emissions

Deposits can cause incomplete combustion, leading to higher carbon monoxide and hydrocarbon emissions. Cleaning restores efficiency and lowers pollutants.

4. Extended Engine Life

Cleaner injectors reduce strain on other engine components such as valves and pistons, indirectly extending the life of the entire fuel system.

5. Lower Maintenance Costs

Routine cleaning can prevent expensive mechanical failures or the need for injector replacement, saving hundreds of dollars over the vehicle’s lifetime.

6. Types of Fuel Injector Cleaners

Fuel injector cleaners can be broadly categorized based on their application method and the type of fuel system they target.

| Type | Application Method | Best For | Advantages |

|---|---|---|---|

| In-Tank Additives | Added directly to the fuel tank. | Routine maintenance for gasoline and diesel vehicles. | Easy to use; affordable; preventive cleaning. |

| Pressurized Cleaning Kits | Connect directly to the fuel rail. | Professional servicing. | Deep cleaning; removes stubborn deposits. |

| Diesel Injector Cleaners | Specially formulated for diesel engines. | Heavy-duty and turbocharged engines. | Removes soot and lubricates injectors. |

| Hybrid System Cleaners | Work for both gasoline and ethanol-blended fuels. | Flexible usage across multiple vehicles. | Versatile and efficient. |

7. How to Use a Fuel Injector Cleaner Properly

Using a fuel injector cleaner is straightforward, but proper technique maximizes effectiveness and safety.

Step-by-Step Instructions:

- Check Your Owner’s Manual:

Confirm whether your vehicle manufacturer recommends the use of additives and note any specific brands or concentration limits. - Select the Right Cleaner:

Choose a cleaner with PEA as the primary ingredient for maximum cleaning efficiency. - Add at the Right Time:

The best time to pour the cleaner is when the fuel tank is nearly empty, before refueling. This ensures proper mixing. - Pour the Cleaner:

Empty the entire contents of the bottle into the fuel tank. Most standard bottles are formulated for 40–60 liters of fuel. - Refuel Immediately:

Fill the tank with fresh fuel to mix the additive evenly. - Drive Normally:

Allow the treated fuel to circulate through the system. Normal driving conditions are sufficient for the cleaning process to work effectively. - Repeat as Needed:

For most vehicles, using a cleaner every 3,000 to 5,000 miles or during every oil change is ideal for ongoing maintenance.

8. Common Mistakes to Avoid

Even though fuel injector cleaners are easy to use, many drivers make simple errors that reduce their effectiveness.

- Using Too Much Additive: Adding more cleaner than recommended doesn’t speed up the process and can cause excess solvent in the system.

- Mixing Different Brands: Combining multiple additives can create chemical imbalances or reduce cleaning efficiency.

- Neglecting Other Components: Sometimes the issue may not be the injector but a dirty fuel filter or air filter.

- Expecting Instant Results: Heavily clogged injectors may require professional cleaning rather than just an in-tank additive.

9. Fuel Injector Cleaner vs. Professional Cleaning

| Aspect | Fuel Injector Cleaner (DIY) | Professional Cleaning Service |

|---|---|---|

| Cost | $10–$20 per bottle | $80–$200 per service |

| Effectiveness | Moderate; good for prevention | Deep cleaning; ideal for severe clogging |

| Time Required | 5 minutes to add, works while driving | 1–2 hours at a workshop |

| Maintenance Frequency | Every 3,000–5,000 miles | Every 25,000–30,000 miles |

| Convenience | Very easy; no tools needed | Requires appointment or mechanic visit |

For everyday maintenance, an additive-based cleaner is sufficient. However, if your engine shows severe misfires or poor performance even after multiple treatments, a professional ultrasonic or pressurized cleaning may be necessary.

10. The Science Behind Deposit Formation

Understanding why deposits form helps you appreciate why regular cleaning matters. Deposits typically originate from three major sources:

- Incomplete Combustion: When fuel doesn’t fully burn, residue sticks to valves, injectors, and piston crowns.

- Low-Quality Fuel: Cheap fuels often contain impurities and insufficient detergents, accelerating buildup.

- Stop-and-Go Driving: Short trips prevent engines from reaching optimal temperatures, encouraging condensation and deposit formation.

These deposits gradually affect injector spray patterns, leading to uneven combustion and performance degradation. Fuel injector cleaners reverse these effects chemically by breaking down these residues into smaller particles that can be burned or expelled safely.

11. Diesel Injector Cleaners: Special Considerations

Diesel engines operate under higher compression ratios and temperatures, making them more prone to soot and carbon accumulation. Diesel injector cleaners are therefore formulated differently from gasoline versions.

Unique Benefits for Diesel Engines:

- Prevent injector sticking caused by soot buildup.

- Restore fuel atomization in common rail systems.

- Improve cold start performance.

- Lubricate fuel pumps and injectors, especially when using ultra-low sulfur diesel (ULSD).

Using a diesel-specific cleaner every few thousand miles can significantly extend injector and pump lifespan while maintaining optimal fuel economy.

12. Myths and Misconceptions About Fuel Injector Cleaners

Let’s debunk some common myths that often confuse vehicle owners:

- Myth 1: Fuel injector cleaners can damage the engine.

→ Fact: When used as directed, reputable cleaners are completely safe for injectors, sensors, and catalytic converters. - Myth 2: Premium fuels eliminate the need for cleaners.

→ Fact: Even premium fuels can’t entirely prevent deposits, especially in direct injection engines. - Myth 3: Once injectors are clogged, additives won’t help.

→ Fact: Additives can dissolve moderate deposits, though severe clogging may require mechanical cleaning. - Myth 4: You need to use them every tank.

→ Fact: Overuse is unnecessary. Cleaning once every few thousand miles is sufficient for most vehicles.

13. Environmental Impact and Eco-Friendly Options

Fuel injector cleaners indirectly contribute to environmental sustainability by improving combustion efficiency and reducing emissions. A cleaner-burning engine emits less carbon monoxide, unburned hydrocarbons, and nitrogen oxides.

Eco-conscious drivers can also select low-toxicity and biodegradable formulas, which reduce solvent emissions and are safer for the environment. Many modern formulations use non-aromatic hydrocarbons that achieve strong cleaning without harmful side effects.

14. Practical Maintenance Tips for Long-Term Injector Health

To maintain a consistently clean fuel system, combine regular injector cleaning with these practical habits:

- Refuel with Quality Gasoline: Choose fuel brands that include detergent additives.

- Replace Fuel Filters on Schedule: Clogged filters can trap dirt that leads to injector fouling.

- Avoid Long Periods of Inactivity: Stale fuel can form varnish and gum deposits.

- Use Clean Storage Containers: If you store fuel, ensure containers are sealed and contamination-free.

- Maintain Regular Service Intervals: Combine fuel system cleaning with oil changes and air filter replacements.

These small practices add up to a healthier engine, better mileage, and lower emissions.

15. Summary: Why Every Driver Should Use Fuel Injector Cleaner

Fuel injector cleaners are one of the simplest tools available to keep your engine in prime condition. They are affordable, effective, and easy to use, offering tangible benefits such as smoother idling, better fuel economy, and longer component life. While they cannot fix severe mechanical problems, they play an essential role in preventive maintenance.

For most drivers, adding a PEA-based fuel injector cleaner every 3,000–5,000 miles is sufficient to maintain a clean and efficient fuel system. Combined with good fuel quality and regular maintenance, it ensures your engine runs smoothly for years to come.

Frequently Asked Questions (FAQs)

1. How often should I use a fuel injector cleaner?

It is generally recommended to use a fuel injector cleaner every 3,000 to 5,000 miles or at every oil change interval. However, drivers who use lower-quality fuel or drive mostly in urban stop-and-go conditions may benefit from more frequent use.

2. Can a fuel injector cleaner fix rough idling or misfires?

If the cause is mild injector clogging, a cleaner can significantly improve idling and performance. However, if misfires are caused by electrical or mechanical issues, such as faulty spark plugs or sensors, a cleaner alone will not solve the problem.

3. Is it safe to use fuel injector cleaner in turbocharged or hybrid engines?

Yes, most modern cleaners are formulated to be compatible with all types of engines, including turbocharged, hybrid, and direct injection systems. Always check the product label to ensure compatibility.

4. What is the difference between fuel system cleaner and fuel injector cleaner?

A fuel system cleaner targets the entire system, including injectors, valves, combustion chambers, and fuel lines, while a fuel injector cleaner focuses primarily on cleaning the injectors themselves. Some products combine both functions.

5. Can I add fuel injector cleaner to a full tank of gas?

Yes, but for best results, add it when the tank is nearly empty and then fill up. This ensures better mixing and more effective cleaning throughout the system.