Tek-102 is a technical designation that appears across engineering documentation, industrial catalogs, and system architecture references. It does not describe a single universal machine or product, but rather functions as a model code applied to components and modules that meet certain expectations of durability, precision, and compatibility. In simple terms, Tek-102 is shorthand for a class of engineered solutions designed to perform reliably in demanding environments.

This type of designation is essential in modern engineering, where complex systems depend on thousands of interlocking parts sourced from different vendors and disciplines. Model codes like Tek-102 allow engineers, technicians, and procurement teams to communicate technical requirements quickly and unambiguously.

The interest around Tek-10-2 stems not from novelty, but from its reputation for consistency. In environments where downtime is costly and errors propagate through entire production chains, the choice of components becomes a strategic decision. Tek-10-2 represents a balance between sophistication and practicality, offering reliable performance without the rigidity or vendor lock-in of proprietary systems.

This article examines what Tek-10-2 represents, how it is used across industries, why professionals rely on it, what challenges accompany it, and how it is likely to evolve as technology continues to advance.

What Tek-102 Represents

Tek-10-2 functions as a reference identifier for engineered components that conform to specific performance and integration expectations. Rather than defining one product category, it signals a design standard associated with precision, stability, and maintainability.

In technical practice, such designations help professionals ensure that parts sourced from different suppliers will behave predictably within a system. Tek-10-2 thus becomes a form of technical language that encodes trust, reliability, and compatibility into a simple label.

Its value lies not in its uniqueness but in its consistency. When a system specification calls for a Tek-102 component, it is calling for a known level of quality and behavior.

Historical Role of Model Designations

Model numbers have been used since the earliest days of industrial manufacturing to classify and standardize parts. As production scaled and systems became more complex, the need for precise identifiers grew.

What began as catalog numbers evolved into structured naming systems that carry information about performance class, versioning, and intended use. Tek-102 fits into this tradition as a designation that has accumulated meaning through repeated use in professional contexts.

Over time, such identifiers become part of institutional memory, guiding decisions long after their original creators are gone.

Core Features of Tek-102

Although implementations vary, Tek-102 components are generally associated with a set of core characteristics.

| Feature | Meaning |

|---|---|

| Durability | Withstands long-term industrial use |

| Precision | Meets tight operational tolerances |

| Compatibility | Integrates with diverse systems |

| Maintainability | Designed for efficient servicing |

| Consistency | Produces repeatable results |

These traits explain why Tek-102 is favored in environments where reliability is more important than novelty.

Applications Across Industries

Tek-102 appears in a wide range of technical environments.

In manufacturing, it supports automation and quality control by ensuring consistent outputs.

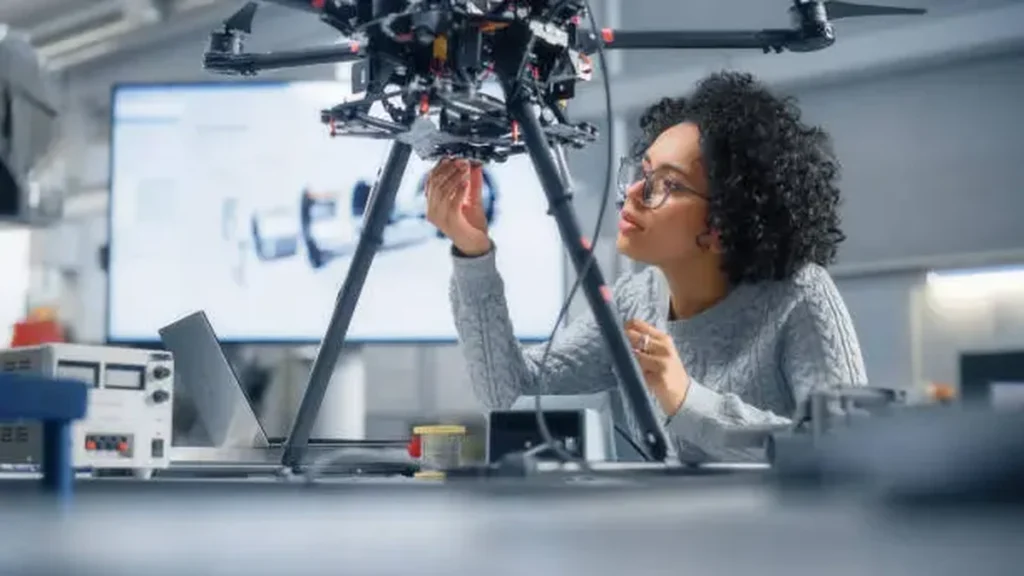

In engineering and prototyping, it provides stable reference points for testing and validation.

In control systems, it enables predictable signal processing and regulation.

In research settings, it supports experiments that depend on repeatable conditions.

Across all of these domains, Tek-102 is valued for reducing uncertainty in complex systems.

Benefits of Using Tek-102

The adoption of Tek-102 brings several advantages.

It reduces integration risk by ensuring compatibility.

It lowers long-term costs through durability and ease of maintenance.

It improves operational efficiency by minimizing errors and downtime.

It supports scalability by allowing systems to expand without redesign.

These benefits are not theoretical; they are practical outcomes observed by engineers and operators.

Expert Perspectives

One engineering consultant notes that precision and durability are essential in automation, where small deviations can halt entire production lines.

A mechanical design specialist emphasizes that compatibility reduces integration complexity and accelerates deployment.

A systems engineer highlights that maintenance-friendly design extends operational life and lowers total cost of ownership.

These perspectives underscore why Tek-102-type components are valued beyond their immediate function.

Comparing Tek-102 with Other Components

| Attribute | Tek-102 | Generic Part | Proprietary System |

|---|---|---|---|

| Precision | High | Medium | High |

| Integration | Flexible | Variable | Restricted |

| Cost | Moderate | Low | High |

| Maintenance | Easy | Moderate | Complex |

| Vendor Lock-in | Low | Low | High |

Tek-102 occupies a pragmatic middle ground between low-cost generic parts and expensive proprietary systems.

Challenges and Limitations

Tek-102 is not without drawbacks.

Incorrect specification can lead to mismatches and performance issues.

Some implementations require supporting infrastructure.

Users may face a learning curve when interpreting technical documentation.

These challenges require planning, training, and cross-team communication.

Future Evolution of Tek-102

As industries move toward smarter systems, Tek-102 designations may evolve to include embedded sensors, predictive maintenance capabilities, and AI-ready interfaces.

Advances in materials may improve performance while reducing energy consumption.

Integration with digital twins and monitoring platforms may further enhance value.

Tek-10-2 will likely continue evolving as a symbol of reliability in a changing technological landscape.

Takeaways

- Tek-102 is a designation, not a single product

- It represents reliability, precision, and compatibility

- It is used across manufacturing, engineering, and research

- It balances flexibility with performance

- It reduces integration risk and operational costs

- It will evolve with automation and AI trends

Conclusion

Tek-10-2 exemplifies how engineering relies on shared language to manage complexity. It transforms abstract expectations into concrete specifications that teams can act upon.

Its enduring value lies in trust: trust that a component will behave as expected, that it will integrate smoothly, and that it will endure.

As systems grow more complex, such trust becomes more valuable, not less. Tek-10-2 is therefore not just a label, but a quiet infrastructure of confidence underpinning modern technology.

FAQs

What is Tek-102

A model designation used to identify reliable technical components.

Is it a specific product

No, it is a class of components with shared traits.

Where is it used

In manufacturing, engineering, control systems, and research.

Why do engineers prefer it

Because it reduces risk and increases reliability.

Will it change in the future

Yes, as systems become smarter and more integrated.